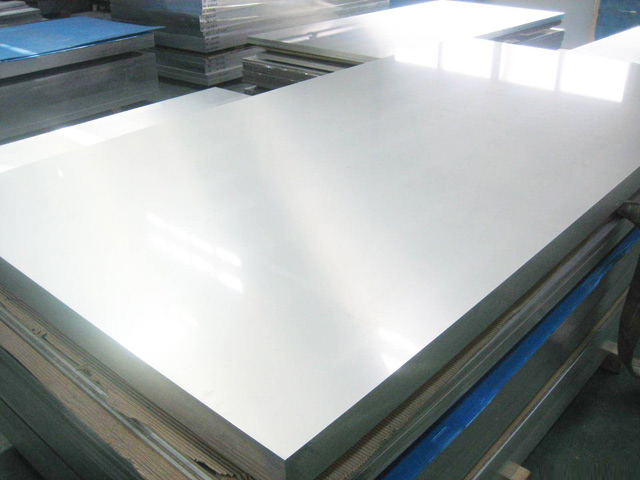

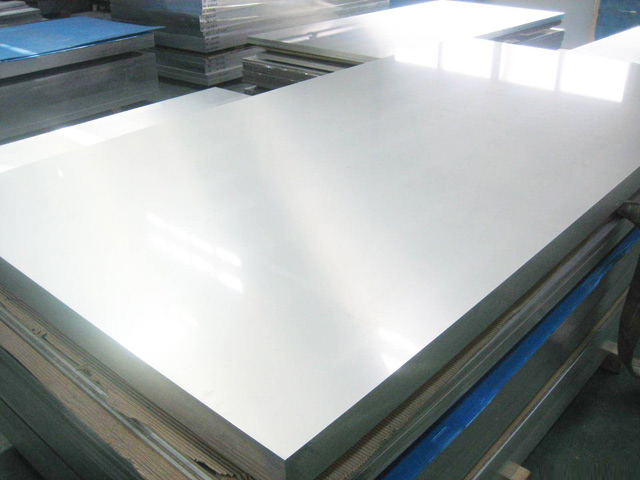

316L stainless steel sheet

316L stainless steel with the addition of Mo, corrosion resistance, particularly excellent pitting resistance. read more

JawaySteel Corporation is the leader in advanced materials with the strongest technical expertise and widest range of products across all our customer segments.

Stainless Steel Strip has been the flagship product of Jaway Steel’s since 1998. Our extensive inventory of stainless steel alloys, along with our six Sendzimir and three 4-high rolling mills make us uniquely equipped to roll precision stainless strip to exacting dimensions. Along with our mills, we offer eight controlled atmosphere annealing lines as well as stainless coil cleaning,[...]

Stainless Steel Strip has been the flagship product of Jaway Steel’s since 1998. Our extensive inventory of stainless steel alloys, along with our six Sendzimir and three 4-high rolling mills make us uniquely equipped to roll precision stainless strip to exacting dimensions. Along with our mills, we offer eight controlled atmosphere annealing lines as well as stainless coil cleaning,[...]

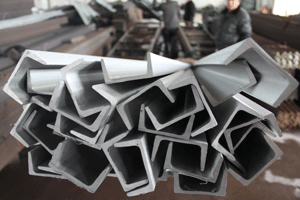

stainless steel channel bars is Jawaysteel Corporation one of the biggest product .We can supply various sizes of stainless steel bars on high quality but factory supply pricing at most competitive rate. This material has been very useful and effective in many industries. [...]

stainless steel channel bars is Jawaysteel Corporation one of the biggest product .We can supply various sizes of stainless steel bars on high quality but factory supply pricing at most competitive rate. This material has been very useful and effective in many industries. [...]

Galvanized Tube products are stocked in both our Shanghai and Jiangshu locations. Diversified JawaySteel of China stocks a vast inventory of Galvanized bar in round, flat, square and hex. Our Galvanized bar products are available in many alloys, including, but not limited to 303, 304, 304L, 316L, 316L and 17-4PH. Additional alloys are available upon request. [...]

Galvanized Tube products are stocked in both our Shanghai and Jiangshu locations. Diversified JawaySteel of China stocks a vast inventory of Galvanized bar in round, flat, square and hex. Our Galvanized bar products are available in many alloys, including, but not limited to 303, 304, 304L, 316L, 316L and 17-4PH. Additional alloys are available upon request. [...]

Products cover a variety of JiangShu stainless steel plate material series: 1.2b plate SUS316L, 310S, 304, 202, 201, 430, 420 oil grinding snow sand, fine grinding 8K mirror plate, titanium plate, deep drawing board, drawing board, and frosted plate. 2 industrial board NO.1/2B SUS316L and 321 310S, 304, acid and alkali resistance, high temperature steel pipe and steel flat steel angle steel plate etc...

Have their own production base, rich production experience, professional production, can be customized according to the demand for stainless steel tubes, products exported to the European Union and other places, the scientific production process to create cost-effective stainless steel, the service life of up to 80 years or more.

Safety, health, environmental protection, ultra fine production process and quality of raw materials, casting products of high quality, the data with international requirements no heavy metals exceeded.

We promise "complete specifications, prompt delivery, high quality, competitive price, ". The unwavering supports you provide, along with the increasing requirements you put contributes to more varied high-quality products with more competitive prices we offer. Win-win situations are always our same pursuit.

Need help with us? Provide service : sales@jawaysteel.com

316L stainless steel with the addition of Mo, corrosion resistance, particularly excellent pitting resistance. read more

Stainless steel angle may require different structure composed of various members of the force, but also for connections read more

Stainless steel bright wire is made of stainless steel as raw material production of all kinds of different sizes and types read more

SUS301 by cold deformation processing so that the intensity of steel, hardness, and retain sufficient toughness. read more