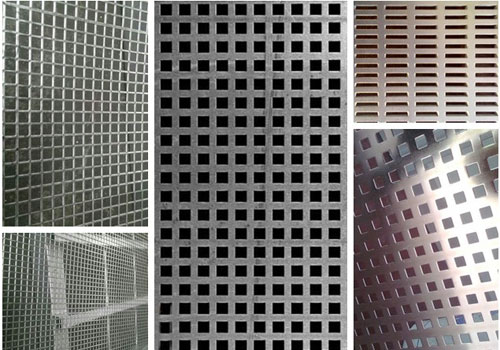

430 stainless steel sheet punching net mesh material is the representative of ferritic stainless steel, punching products are widely used in construction, decoration, food machinery, household appliances and other industries. 430 stainless steel punching raw materials in the cold rolling pickling has been extended with the shell furnace annealing process, so the tower requirements are particularly high. In the hot rolling area, the tower blockade rate has been more than 30 percent, the tower is too large will lead to folding, so that the high volume, high renovation costs, through the process analysis, although the impact of tower factors are more, but the key is still Finished plate shape control experience. Because of this, the discussion of plate-shaped control to reduce the 430 stainless steel tower has a great effect.

Flexion strength and pull-in strength, 430 stainless steel sheet punching net processing hardening, easy to initiation rebound and cross-cutting damage, so the facilities of the wet, stiffness and wear resistance must be good, the general use of aluminum bronze (PVD, CVD surface treatment). Thermal conductivity, heating expansion, so the use of cooling but good performance of water-soluble lubricating oil.

In order to avoid the appearance of the lack of oil and the implementation of lubricants, the general appearance of the steel plate or the use of lubricating oil treatment of steel plate. In the vicinity of the room temperature hardening of the special properties affected by the temperature, forming by the temperature and speed of the impact is very large. Generally high temperature, high speed conditions, n value decreases, forming pieces deteriorated. So the use of temperature effects of the temperature of the temperature processing methods can be very good stamping performance.

430 stainless steel sheet punching net

Punching the current situation of the plate

Stainless steel punching wire business unit Since the production of 430 stainless steel since 2014, it is appropriate to use until now under the advanced hybrid rolling technology. Mixing and rolling technology refers to the use of a heating furnace in the heating furnace is suitable for the use of carbon steel, two additional heating furnace stainless steel, steel in accordance with stainless steel carbon steel, stainless steel or stainless steel, stainless steel and other forms of steel production. Up to now the mixed standard pattern is basically 2: 1 or 1: 1 in the form of rolling two pieces of 430 and then rolling a piece of carbon steel.

The advantages of hybrid rolling technology is able to go through the combination of carbon steel and stainless steel pipe to increase the production rate, while the formation of a stable oxygen in the rolling surface of the film, to protect the appearance of stainless steel quality. But this form does not affect the impact of plate is difficult to implement learning. Flatness precision has a superficial process, especially the rolling plan head is particularly surface. Compared with other plate type, such as FSU, there is no sub-furnace learning, so that plate-type self-learning more difficult, and stainless steel concentrated rolling phase, shape control is relatively poor, the demand for the operation of the number of people to carry out the number of artificial intervention to control the strip , Because the growth of the plate under satisfactory rolling conditions is the main internal essence of the discussion.